Step-by-step recommendations for making a cabinet-bed with your own hands

With small apartments in which a large number of people live, there is a need to save space. The issue of furniture placement can become an acute issue in a children's room, especially if it is single, and several children of school or preschool age are forced to sleep in it. To save space, you can buy a folding bed. You can create a drawing and make a wardrobe bed with your own hands. This will significantly save financial expenses and will allow you to create a bed of the required dimensions, taking into account the color scheme of the room and the decorative elements present in it.

Preparation of materials and cutting

Before starting the bed manufacturing process, you must have a drawing, following which you can make a wardrobe-bed with or without additional shelves. A detailed layout of parts will help create a quality bed as quickly as possible, which will function correctly.

Such schemes most often involve the manufacture of beds with sizes 1800 * 2000, 2120 * 1715, 2040 * 2200, 1731 * 2020. These make double beds. Single ones are most often intended for children's rooms, therefore they are smaller. Since their installation is carried out independently, it is possible to create a drawing of the size of the bed, depending on the availability of space, the age of the child and the possible use of this bed by younger children after the older ones are older. To create a transformer bed, drawings must be as accurate and clear as possible.

To make a wardrobe bed with your own hands, you will need such tools:

- Drill;

- Screwdriver;

- Jigsaw;

- Saw;

- File;

- Pliers;

- Roulette;

- Level;

- Screwdriver;

- Joiner pencil;

- Sandpaper with different numbers of abrasiveness;

- Furniture screws;

- Self-tapping screws.

This is a minimal set of tools; in the process, others may be required.

Instruments

InstrumentsIt is also necessary to have the following materials:

- Furniture plates or chipboards;

- Wooden beams;

- Wooden boards;

- Hinges for fastening;

- Corners;

- Swivel mechanism;

- Materials for decorating;

- Materials for the manufacture of legs.

It is also a minimal set of materials. Cutting is done according to the drawing. It is done like this:

- Using a tape measure and a pencil, all the details of the future cabinet are made in the form of patterns according to the data from the drawing;

- For patterns, you can use connected sheets of Whatman paper or wallpaper;

- Each item needs to be signed;

- Identify the joints and fastenings of the transformation mechanism.

Materials

MaterialsFrame assembly

To assemble the frame, you need to know the clear dimensions of the proposed bed. They depend on the size of the bed and on the type of bed: single or double. For the frame, you need 2 side plates located along the frame, 2 side plates for fastening along the width of the bed, as well as the rear base. The back wall will occupy the entire area of the so-called cabinet, so it should be larger in size than the mattress that will be on the bed. Based on these considerations, it is recommended that the frame be made 15 cm wide and 40 cm large in length (a margin in length is necessary for folding).

Having decided on the size of the side plates and the back wall for the frame, you must:

- Make cutting on a chipboard panel or on a furniture plate, using patterns for this;

- Cut the parts with a jigsaw, sand them thoroughly, fringe the edges;

- Prepare a layout for fasteners, transferring data from patterns to plates;

- Connect the shield with furniture screws, for the reliability of their fastening, drill a hole in advance with a drill and a drill with the possibility of preparing a groove for the head and fasteners (connection with screws should be carried out every 25-35 cm).

We carry out a cut

We carry out a cut Grinding coating

Grinding coating We connect the elements with fasteners

We connect the elements with fastenersMattress box

Creating the mattress box yourself is the most difficult part in making a wardrobe-bed. When cutting, cutting parts from furniture plates (or from other materials), carefully follow the numbers indicated in the drawing. Thanks to this, it will be possible to create a box that will correspond to the size of the frame.

To make the box you need:

- Two side walls that can be diagonal;

- One side wall;

- Bottom (plywood is the most suitable material for manufacturing).

How to make a box:

- It is necessary to cut and cut the plywood bottom in the same way as the back wall for the frame;

- To make back and side walls, to process their edges with sandpaper and a fringing tape;

- Attach the side and rear walls to the plywood bottom with furniture screws. It is necessary to adhere to a distance of 25-30 cm between the screws;

- Around the perimeter of the resulting structure, it is necessary to lay a wooden beam, which will serve as a support for the mattress pad. It is advisable to use a beam measuring 50 * 50 mm. It is fastened with wood screws to the side walls;

- To create a device for the mattress pad, edged boards are used that are screwed to a wooden beam. The length of one board should be such as to get from one edge of the beam to the opposite. They are placed in the same plane as the plywood bottom. The distance between the boards is 10-20 cm.

We carry out a chipboard cut

We carry out a chipboard cut Making the side and back wall

Making the side and back wall We lay lamellas

We lay lamellasMounting the transformation mechanism

The lifting mechanism performs the function of the movement of the box in relation to the immovable frame.

How to mount:

- The hinges of the articulated mechanism are screwed onto the bed box and frame. The main support in this case should fall on the frame, because it is immovable;

- The dimensions of the box and frame are adjusted to each other, and the mechanism is connected;

- This work must be done with an assistant;

- After mounting the transformation system, it is necessary to raise the box, check its compliance with the size of the frame;

- For smooth installation of the articulated mechanism, it is necessary to use a level so that the bed rises evenly and thus reliably rests on the same plane with the frame. A uniform line should be achieved at the junction of the upper edge of the frame and the lower edge of the box.

To facilitate the transformation, you can use additional parts that simplify the movement of the mechanism (gas shock absorbers, counterweight). Such mechanisms are especially necessary if a baby bed or teenage bed is made. It is not recommended to allow children to fold and unroll a folding bed on their own, but even in this case, it is necessary that the children can independently lay out the bed without any help, therefore, the transformation system built into the cabinet with their own hands should be easy.

Steps 1-2

Steps 1-2 Stage 3-4

Stage 3-4Create a headboard

The head of the transformer cabinet should be made of soft material, especially if the bed is for children. It is desirable to make soft not only the headboard, but also the lower part of the side walls of the frame. The easiest option for a soft headboard that you can make yourself - soft foam padding. The role of foam rubber can also be performed by a synthetic winterizer.

How to make a headboard:

- Folding material in several layers;

- This material must be sewn with a beautiful fabric with decorative elements or quilted stitching;

- For ease of care, you can create a detachable beating, with hidden zippers. It will be convenient to remove, wash and put it on again;

- The height of the soft head should be at least 60-70 cm, and preferably about 1 m. This will ensure the presence of a soft upholstery under the back of a seated person at the head of the bed. For the same reason, the same softening upholstery should be prepared for the side walls of the frame;

- The height of the foam pillow on the side walls of the frame should match the height of the same upholstery at the head;

- The prepared upholstery can be attached to the frame or to the wall using screws and fabric (or made from elastic) loops. If the padding is not removable, then the back of the fabric cover can be attached with a stapler.

We cut sheets

We cut sheets Making holes for buttons

Making holes for buttons Glue the foam

Glue the foam Fasten the upholstery

Fasten the upholstery We mount buttons

We mount buttonsLegs

The legs for such a bed must be movable and turn around at least 180 ° C. In such cases, it is convenient to use metal legs connected together and representing a metal bar with corresponding bends.

How to fix:

- Make measurements of the height of the box above the floor, determine the height of the legs;

- Measure the width of the box. Calculate the length of the metal strip;

- Weld, grind, varnish a leg or order a finished one;

- Prepare holes for mounting on the box and on the leg;

- Such legs are attached to the bottom plank of the box so as to attach to a wooden beam in the middle;

- Check legs for turning.

When unfolding the transformer, the legs must be rotated 180 degrees and put a bed on them. When the box is lifted, the legs are tucked so as to be hidden inside the so-called cabinet. In addition, a metal bar connecting two legs (or a straight bar of a molded leg) simultaneously performs the task of holding the mattress on the mattress pad. Thus, its movement during folding and unfolding of the bed is excluded. For the same purpose, you can install stops at the upper edge of the mattress pad. Limiters can be horizontal bars. There may be several legs, but in this case the folding process is complicated. The leg should be strong to support the weight of the box, mattress, bedding and sleeping people.

We measure a box

We measure a box We get special legs

We get special legs Make holes

Make holes Fasten the leg

Fasten the legDecoration and fittings

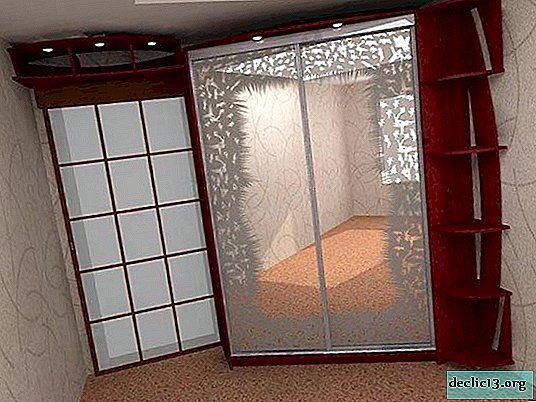

With the help of decorative elements, you can completely hide the presence of a transforming bed in the room. There are many ideas for decorating the bottom trims of a bedside box that looks into the room. One of the most beautiful and simple options is to create an imitation of a three-door or four-door cabinet.

The doors can be imitated using wooden planks and handles, supposedly designed to open such doors. On one of the doors you can put a mirror.

Another good option to hide the presence of a transforming bed in the room is to mount this closet in the furniture wall, creating a bed of furniture plates of the same color as the wall. Next to other parts of the wall, the cabinet will look quite natural, especially if you add decorative elements such as handles and trims. At the same time, neighboring cabinets in the wall can be used to store bedding, which will greatly simplify the process of cleaning the bed every morning.

Installation

Before making the installation with your own hands, it is advisable to cover the transformer with varnish, which will prevent the rapid deterioration of wooden elements, extend the life of the product, and prevent rotting of wooden elements.

How to install:

- Installation involves mounting the frame to the wall. This will ensure structural stability;

- A mattress is placed on the mattress pad;

- It is advisable to provide places for storing bedding - this may be a bedside table, which is located next to the bed or even attached to the box;

- These bedside tables should be large enough to accommodate not only bedding, but also pillows.

As can be seen from the information described in this article, the production of a transforming bed in the form of a folding cabinet independently at home can take a lot of time. With careful planning and production of accurate drawings, you can create such a bed quickly enough, especially if you have assistants. Savings in financial costs for self-made wardrobe beds can be up to 70%.

We connect the bed and the wardrobe

We connect the bed and the wardrobe Reinforcing

Reinforcing We mount a facade

We mount a facade