Purpose of furniture profile, selection tips

In the production and design of cabinet furniture, accessories from high-tech materials are actively used. The strength and durability of products depend on the quality of connecting, trimming, frame, supporting elements. Molded fittings are furniture profiles used to create finished structures. For its production, various materials are used, differing in shape, size, technical, operational characteristics.

What is a

In the manufacture of furniture structures, accessories play an important role. With its help, parts can be combined into a single system or used for finishing finished products. The furniture profile is a hardware made by rolling, bending, casting, stamping - it depends on the properties of the source material. Semi-finished product has important advantages:

- decorative function - a variety of colors, shapes, materials of manufacture plays a chord role in the design of products, determines the overall style of the furniture ensemble;

- structural component - a profile for furniture serves as a supporting and connecting element, serves as a frame for filling MDF facades with panels, wood, veneer, glass;

- protection against mechanical damage - thanks to the clear dimensions of the profiles, it is possible to observe the strict geometry of furniture facades, countertops, doors, mirrors;

- durability of products enclosed in furniture profile. Structural elements are protected from moisture on the ends and edges, the structure of the facades, coupe is preserved;

- insignificant weight - the fittings are made of light materials, therefore the products do not load the furniture elements, do not burden the products, but at the same time have high mechanical strength.

Furniture profile is produced as molded semi-finished product of various sections, sizes, shapes. Depending on the purpose, they distinguish between frame-type options for facades, false cornices, end plates for countertops, sliding elements of sliding wardrobes, handles, frames, planks, edging, modules for drawers, beds.

Appointment

In the manufacture of cabinet furniture, such elements are widely used that simultaneously perform a decorative, protective and supporting function. The use of profiles allows you to produce factory products, to produce furniture according to individual drawings. The purpose of the furniture profile of various types and designs:

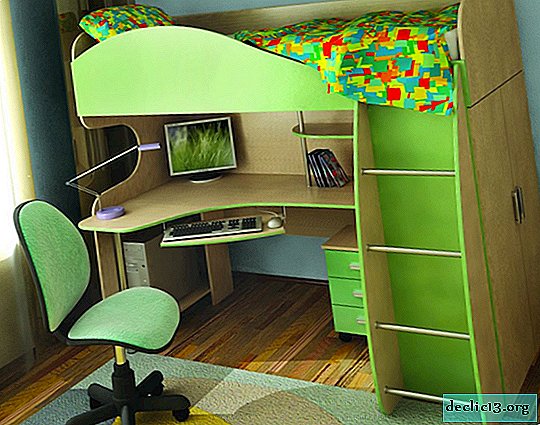

- facade - frame structures made of furniture profile are filled with glass, mirror panels, plastic, MDF boards, a shield made of natural wood. A strong frame base is used in the manufacture of kitchen sets, furniture for bedrooms, living rooms, nurseries, corridors, wardrobes;

- false cornice - multi-relief products are used to decorate the upper parts of cabinets. Cornices have a front side, a slice and a back, can be solid and glued from several blanks. Widely used for furniture decoration according to individual drawings;

- side overlays - such profiles are used for frontal processing of kitchen countertops. Mortise products act as a protective edging, prevent moisture and dirt from entering the end surface of the countertop, give the parts an aesthetically attractive appearance;

- connecting, fixing, end strips. Fittings are used to fix furniture parts without the use of glue. At the same time, functional products protect the edges of countertops, facades, panels from moisture, debris, and dirt. End plates perform a decorative and protective function;

- profile for sliding systems. Used in the manufacture of door designs of sliding door wardrobes. With the help of a closed or open profile, door frames are framed, a separate type of hardware is the handle profile, thanks to which it is easy to move the canvas along the guide rails.

The use of protective-decorative and connecting-supporting profiles of various shapes and designs allows you to implement custom design solutions, as well as hide the gaps between furniture elements.

If the furniture is made without decorative legs, the gap between the bottom of the structure and the floor is closed with a socle made of waterproof laminated chipboard or MDF (according to the case material). To extend the life of the base, a water-repellent profile can be installed under it on the sealant to prevent water from entering the base plinth.

Side pad

Side pad Overhead

Overhead For sliding systems

For sliding systems Front

FrontMaterials of manufacture

Profile fittings are made from materials that differ in structure, obtaining flexible and rigid furniture elements. Due to this, it is possible to process rectilinear and curvilinear parts, to perform edging of complex elements. The main materials for the manufacture of furniture profiles:

- aluminum is a light metal of high strength and has a long service life. Due to the addition of copper, silicon, silver, manganese, zinc, magnesium, titanium to the alloy, it is possible to obtain a profile that is resistant to corrosion, chemical and mechanical influences. Aluminum fittings have the required ductility, to protect against damage, the metal is coated with a special film. The predominant color scheme is gold, silver, champagne, there are shades of wood and bright colors;

- MDF furniture profile. The products are made of medium density fiberboard with a coating that imitates various types of natural wood. The fittings are characterized by ease of installation, wide color gamut, pleasant texture, environmental cleanliness and durability. MDF products are lined with PVC film, natural veneer, eco-leather. Execution options: frame, support, typesetting profile, eaves, overlays, accessories under an insert;

- PVC profile for furniture. Plastic material is used to decorate the ends of MDF and particleboard panels. The edging of polyvinyl chloride is characterized by a flexible structure, it can be overhead and mortise type of installation, maybe with a girth and without it. The main advantage is ease of installation, wide color gamut. PVC profile allows you to hide the aesthetic flaws of the furniture, prevent wetting and swelling of the ends of wood-particle and fiber boards from moisture.

Anodized aluminum, plastic and MDF are the main materials for the manufacture of furniture profiles. Less often, for its production, a wooden shield or natural wood is used, on which a recess is made under the insert of the facades. Such products are used to create frame structures, since it is economically unprofitable and impractical to process ends and gaps with a rigid wooden profile.

Aluminum

Aluminum MDF

MDF PVC

PVCShape and size

The range of profile fittings for the production of furniture structures is quite extensive. The cost of a running meter of a profile for furniture depends on the material of manufacture, the complexity of the configuration, the presence of decorative finishes. The length of the accessories starts from three meters. What shape are the products:

- PVC profile - distinguish overhead products with a U-shaped edging of a rigid and flexible type. Rigid linings are used for edging the direct facades of chipboard, flexible ones are used to process the ends of straight or rounded parts. Mortise T-shaped PVC profile provides a solid fastening with a facade, for installation you need to make a groove with a milling cutter (tooth - 2.8-3 mm, depth - 10 mm), products come in girth, without girth, there are also flexible and soft furniture profile and rigid fittings. Profile dimensions are determined by the width of the panel, facade, countertop - 16, 18, 32 mm;

- frame aluminum. The standard form is square, rectangular, produce products with a rounded front side (Giff design). Distinguish between narrow and wide aluminum parts. The width of the mounting groove for installing glass, acrylic, mirror, plate MDF filling is from 4 to 10 mm, the length of products for assembling frame structures can be 5000, 5200, 5500 or 6000 mm (depending on the manufacturer). A separate category of profiles is products with a radial front part;

- handle profile made of aluminum. The front fittings of a mortise or laid-on installation method are mainly used for installation on sliding wardrobes and kitchen sets. The sectional shape of the profile is L, F, H, C, T, P shaped. Variable sizes - from 60 to 2000 mm, determined by the type of furniture design. Can be installed on facades made of MDF boards with a width of 16, 18, 19, 22, 25 mm. The furniture design also uses hidden triangular handles on drawers and shelves, there are profile options with LED backlight;

- MDF furniture profile - there is a wide range of MDF profiles from fiberboards of various configurations. Among them, lining C, D, P shaped. The length of the products is 2795 mm, the thickness of the frame MDF profile is 16-22 mm, the width is 50-60 mm, when faced with the finish film, PVC, veneer, the width is 60-80 mm, the groove size is 4-10 mm. The profile is used in the manufacture of bedside tables, beds, chests of drawers, wardrobes, and is used as a framework, linings, cornices, pilasters, socles.

The choice of furniture profile depends on the function that the product performs - decor, protection, support, connection. Each manufacturer indicates the size range of products, the shape of the section, the parameters of the accessories in width and thickness with the indication of the running meter in one whip of the goods being sold. This helps to navigate when calculating the required amount of material.

The nuances of choice and use

At the discretion or at the request of customers at furniture enterprises use various accessories. Much depends on the shape (straight, rounded) and the filling of facades, doors. When to give preference to aluminum:

- To obtain rigid structures for overall furniture details, an aluminum frame profile is used. Light alloy metal can withstand high bending loads;

- aluminum is more effective at furnishing furniture for damp rooms. It well protects the ends of countertops, the edges of facades made of MDF, chipboard, therefore it is used to connect the modules;

- the surface of aluminum is resistant to corrosion processes, well withstands mechanical and chemical effects. Due to the flexibility of the material, the fittings can be given a complex shape;

- decorative attractiveness of aluminum is clearly manifested in the manufacture of furniture for interiors in the modern, techno, loft, high-tech style, in the combination of metal, glass, mirrors;

- aluminum does not fade, withstands high temperatures well, does not ignite, provides a strong connection of furniture design elements. It is chosen when it is necessary to obtain durable furniture products, the details of which are enclosed in a rigid metal frame.

The profile for furniture facades made of MDF to a greater extent performs a decorative function. With it, you can create sets of furniture from materials of different textures. MDF products are chosen for trimming and filling facades of wood, plastic, acrylic, mirror, glass materials. When prefer MDF hardware:

- it is necessary to use a product with a non-standard section shape;

- it is required to make trimming of parts according to individual sizes;

- the furniture is installed in a dry room, the product does not get moisture;

- the headset design uses a warm range of wood shades;

- you need to assemble furniture with minimal time without the use of special equipment.

PVC models are used less often, it differs from the edge by an important advantage - the edging does not need to be cut in width. Soft PVC fittings well bend around the curved edges of the furniture, allow you to process structurally complex parts, it is used to manufacture products of the budget and economy options, but does not differ in durability and practicality.

Without a furniture profile, it is difficult to create complete structures and combine individual elements into a single whole. Products made of MDF, aluminum, PVC are widely used in furniture production, performs an important protective and decorative function.